Agimix Side Entry Agitators have been designed to deliver high efficiency in the homogenization of liquids in medium and large industrial tanks. With lateral installation and the motor positioned outside the fluid, they are ideal for continuous processes, ensuring energy savings, safety, and low maintenance.

Find below the most frequently asked questions about Agimix Side Entry Agitators. We provide clear and objective answers to help you better understand their operation, applications, and advantages as an essential piece of equipment for industrial processes.

The Agimix Side Entry Agitator is installed on the side of the tank, with the motor positioned outside the fluid, making it ideal for continuous operation. On the other hand, the vertical agitator is mounted from the top and is usually used for intermittent batch processes.

The Agimix Side Entry/Horizontal Agitators serve a wide range of industries, such as chemical, pharmaceutical, food, cosmetic, water treatment, pulp and paper, mining, and petrochemical, always configured according to the specific requirements and standards of each industry.

Yes. Customized versions allow mixing of medium to high viscosity liquids (up to ~15,000 cP or more), with specific impellers and speed control.

Yes. The Side Entry Agitator can be installed in existing tanks with a side cut and dedicated flange, without major structural modifications.

Evaluate the tank volume, rotor type, viscosity, and agitation objective. A process engineering design or CFD analysis can determine the ideal power.

Yes. Its side-mounted installation eliminates the need for a top opening or elevated structure, reducing the footprint and installation cost.

Although Side Entry Agitators are advantageous in terms of space, it is important to consider that they may not be the best choice for all applications. For example, in applications with abrasive solids or gas dispersion, Vertical Agitators may be more suitable.

Yes. Its motor can be equipped with a frequency inverter, allowing rotation adjustment (rpm) according to the viscosity and the type of mixture.

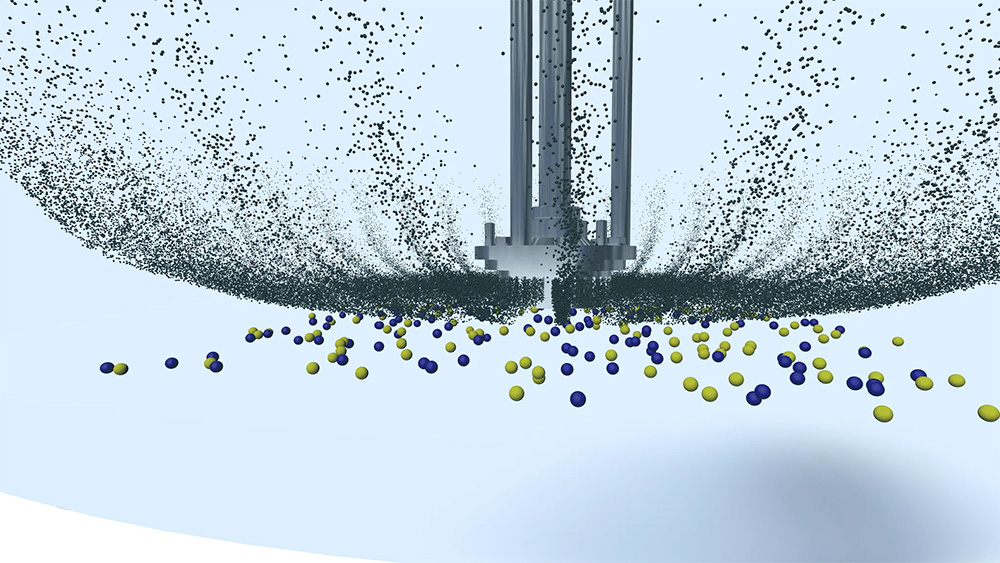

Yes. The Side Entry Agitator is effective at keeping small solid particles in suspension in miscible liquids, preventing sedimentation.

The Industrial Side Agitator from Agimix is designed to maintain homogeneous mixing, promote solid dissolution, liquid emulsification, and prevent component separation in tanks. Agimix Side Agitators are ideal for processes requiring continuous operation and high efficiency, optimizing production and ensuring the final product quality.

To choose the ideal agitator, consider the type of product, viscosity, tank volume, and mixing time. Agimix specialists can assist in selecting the Side Agitator or Horizontal Agitator that best suits your conditions, ensuring high efficiency and cost savings in the process.

Retrofitting is the modernization of older industrial agitators, involving the replacement of parts and technological upgrades to improve performance and efficiency. For Agimix Side Agitators, retrofitting is recommended when there is wear, loss of efficiency, or the need to adapt to new process requirements.

Retrofitting provides increased operational efficiency, reduced maintenance costs, extended agitator lifespan, and compliance with current standards. At Agimix, retrofitting of Side Agitators is a cost-effective solution to keep your equipment modern and reliable, avoiding the need for a larger investment in a new agitator.

The main applications of the Agimix Industrial Agitator include mixing of chemicals, formulation of cosmetics and pharmaceuticals, food and beverage production, water and effluent treatment, and mining and petrochemical processes. It is a versatile equipment that adapts to various industrial needs.