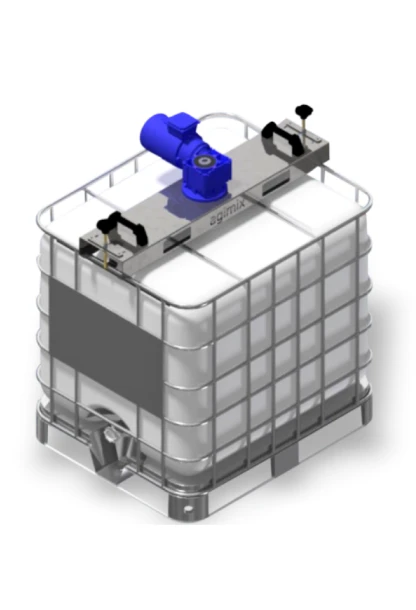

The Agitator / Mixer for IBC 1000L Containers from Agimix is the ideal solution to ensure the homogeneity of products stored for long periods or prone to phase separation. Perfect for the pre-preparation of solutions such as paints, varnishes, oils, syrups, sorbitol, additives, and sanitizers, this equipment ensures the quality and consistency of your products. Designed for ease of use, the Mixer for IBC 1000L fits perfectly into the metal structure of the container and can be adjusted for various models. With multiple construction options, it offers flexibility and efficiency to meet the specific needs of each industrial process.

Features of the Agitator / Mixer for IBC 1000L

Advantages of the Agitator / Mixer for IBC 1000L

Mixing Capacity: Up to 1000 liters.